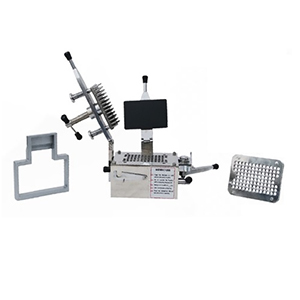

Manual Capsule Filling Machine

| Model | CF 300 Standard | CF 300 GMP | CF 300 cGMP |

| Number of Hole | 300 | 300 | 300 |

| Contact Parts MOC | AISI 304 | AISI 304 | AISI 316 |

| Body MOC | MS | AISI 304 | AISI 304 |

| Coating | HCP | EP | EP |

| No of Change Parts | 1 | 1 | 1 |

| Capacity / Hour | 6000 | 6000 | 6000 |

| Sequence of holes | 25 X 12 | 25 X 12 | 25 X 12 |

| Numbers of Loading Trays | 3 | 3 | 3 |

| Machine Weight (Kg) | 45 | 45 | 45 |

- cGMP Model

- All Contact Parts Are Manufactured from AISI 316

- All Non-Contact Parts Are Manufactured from AISI 304

- Eccentric cam Pin and Washer Made Out of OHNS Tool Steel

- Suitable for the Capsule Size 0, 00,1,2

- With Three Loading Plates

- With Powder Collection Tray

- With Capsule Press Plate

- With Spreader

- With Powder Collection Tray

- Sequence of Holes 25 X 12 = 300 Nos

- Production Output up to 6000 Capsules / Hour

- Net Weight of the Machine 50 Kg

- Overall Dimension 405mm (L) x 300mm (W) x 455mm (H) approx.

- Easy to Operate & Fill

Capsule Auto Loader

| Model | CAL 300 |

| Type of Machine | GMP |

| Capacity / Hour (No. of Capsules) | 30,000 |

| Sequence of Holes – 25 X 12 | 300 |

| Number of Loading Tray | 1 |

| Main Motor | 0.25 HP |

| Suitable for Capsule Sizes | 00/00/0/1/2/3/4/5 |

| Machine Dimension LXWXH -mm | 630X430 X 780 |

| Machine Weight (Kg) | 95 |

- cGMP Model

- All Contact Parts Are Manufactured from AISI 316

- All Non-Contact Parts Are Manufactured from AISI 304

- Sequence of Hole 25 X 12 = 300

- With One Loading Tray

- With Capsule Combinations of Sizes, 00, 0,1,2,3 & 4 Through Change Parts

- Loading Rack with Engineering Plastics, Accurate Positioning & Reduce Noise

- Motor Transmission Box with Worm Gear Structure, Low Noise & Stable Work.

- Drive System Is Fully Enclosed and Open-Type Sowing Table, Easier to Clean

- Easy to Operate & Fill

- 0.18 kW, Single Phase Motor

- Simple To Operate, Can Be Handled by Semi-Skilled Person

- Machine Stop Automatically After Loading Of 300 Capsules

- Auto Loader Speed can fill loading plates of 2 – 3 capsule filling machines

- 300 Capsules Loading Cycle time is 28-40 Seconds

- Suitable for Hard Gelatine, HPMC & Veg Capsules in 00, 0, 1, 2, 3, 4 & 5 sizes

- Auto Loader Size 630 mm X 430 mm X 780 mm

- Net Weight Approx 80 Kg

Semi-Automatic Capsule Filling Machine

| Model | SA 9 |

| Number of Auto Loader | 1 |

| Contact Parts MOC | AISI 316 |

| Suitable for the CapsuleSize | 0, 1/2, 3/4/5 |

| No. Of Holes in Loading Ring Sizes, 0, 1/2, 3/4/5 | 480/ 540/ 600 |

| Per Hour Output as per Size, / Hour | 22000 / 25000/ 27000 Capsule |

| Loader Drive at Fix speed 45 Sec/plate | 0.25 HP |

| Filling Table Drive with 2 to 14 RPMThrough VFD | 0.5 HP |

| Auger Drive with 200 to 400 RPM through VFD | 2.0 HP |

- The Machine Is Constructed in A Mild Steel Angel Welded & Powder Coated Frame, The Product Contact Parts Are Built with Stainless Steel 316 Grade & All Covering Build with Stainless Steel 304 Grade Sheet Other Machine Parts Like a Cam, Gears, Shafts Are Bolted.

- The Polishing & Sorting of Capsule Can be Attached (optional)

- Empty Capsules Are Separated Automatically Once Loaded and Thus Requires No Manual Operation of Turning by Hand

- As The Loading Ring Performs One Complete Rotation, The Disengagement of Loader Occurs Automatically

- Semi-Automatic Capsule Filling Machine Boasts of A PLC Controlled Digital to Demonstrate the Operations

- The Auger of This Filling Machine Comes with Four Speed Range So That Different Type of Powders & Pellets Can Be Filled.

- The Drug Hopper Has an Improvised Design Which Allows for Lesser Time Consumption When the Powders Are Dismantled and Unloaded.

- The Loader of The Machine Is Automatically Declutched as Soon as The Loading Rings Get Filled. This Minimizes the Need forAttention of The Worker to Achieve the Target of Maximizing the Output.

- Dosage Accuracy Is Achieved in The Machine as The Table Has Infinitely Variable Filling Speed.

- Machine Can Handle Different Variants of Powder Ranging from Hygroscopic to Free-Flowing Ones.

- A Quick and Safer Operation of Closing and Ejection Is Achieved with The Help of Automatic Capsule Closing System.

- Pneumatic Closing Station Makes Use of An Electric Sensor to Operate on The Pneumatic Cylinder in Order to Simplify the Process of Closing.

- The Filling Machine Makes Sure That the Capsules After Getting Filled Are Closed Vertically in Order to Prevent Powders from Getting Spilled and Hence Lower the Rejection Rate of The Entire Process. While Filling the Pellets, This Procedure Proves to Be Beneficial and Is Obtained by Allowing for Two Speeds of Auger and Nine Variable Speed of The Filling Table.

- Modular Type Hopper Eases the Process of Dismantling and Makes It Quicker That Is Done While Cleaning It. It Helps in Lessening the Change-Over Time Between the Batches.

- With Ring Loading Station, The Filled Capsule Output Capacity Experiences a Substantial Increase

- The Ejection Chute Accommodates a Large De-Dusting Screen That Aids in The Powder Separation Adhering to The Already Filled Capsules.

Automatic Capsule Filling Machine

| Model | AF 40 |

| Number of Auto Loader | 1 |

| Contact Parts MOC | AISI 316 |

| Suitable for the CapsuleSize | 000, 00, 0, 1,2, 3,4,5 |

| Product Can be Filled, | Powder, Pellets, Tablets |

| Output With Powder/Hour | 40,000 Capsules |

| Output With Pellets/Hour | 26,000 Capsules |

| Vacuum Pump Drive at 30 CFM | 3.0 HP |

| Total Power | 5 kW/ 440V / 50 Hz / 3 Phase AC |

| Compress Air Requirement @6 Bar | 8CFM @ 200 Litre / Minute |

| Size (MM): (L) x (W)x(H) | 950x 850 x1930 |

- It Designed with Indexing Motion and Multi-Position Tamping Method to Complete Capsule Orientation, Separation, Filling, Closing and Ejection

- Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

- Machine can be in lined with other Machines like, Capsule Sorter Elevator, Capsule Conveying System, Capsule Polishing Machine, Dust Extractor, Damage Capsule Sorter, and Empty Capsule Ejector

- Filling Table of The Machine Has Variable Speed That Aids in Achieving High Dosage Accuracy

- The Design and Construction of The Machine Encompasses All the GMP Aspects of Pharmaceutical Sanitation

- The Machine Is Constructed in A Mild Steel Angel Welded & Powder Coated Frame, The Product Contact Parts Are Built with Stainless Steel 316 Grade & All Covering Build with Stainless Steel 304 Grade Sheet Other Machine Parts Like a Cam, Gears, Shafts Are Bolted.

- Working Atmosphere Ambient Temperature 21℃ ± 3℃, 40 to 45% RH (Relative Humidity)

- All The Drive Elements and The Cabling at The Bottom Side Separate Panel

- Crevice Free Smooth Stainless Steel Pharmaceutical Grades

- Automatic Intermittent Motion Driving Zone Completely Separate at Bottom and Production Zone at Upper Side

- Fill Weight Can Be Easily Achieved by Dosing Disk Thickness; The Weight Variation Can Be Maintained ± 3% By Accurate Dosing Disc for Powder

- Similar Fill Weight Can Be Easily Achieved by Pellets Filling Tool Thickness and Cavity Size. The Weight Variation Can Be Maintained ±5% By Accurate Tool.

- Powder Sensor Maintains Constant Level of Powder in The Dosing Chamber and There Will Alarm in Case of Low Level of Powder in Dosing Chamber.

- Pellet Sensor Maintains Constant Level of Pellets in The Hopper and There Will Alarm in Case of Low Level of Pellets in Hopper.

- Easy To Operation by Central Control Touch Screen With 50 Recipes to Change Dosing Disc, Tamping Pins, Pellets Filling Tool, Capsule Feeding & Orientation Parts, Capsule Segments.